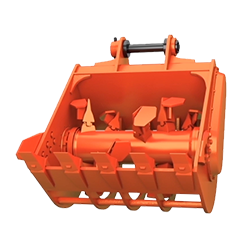

Hydraulic Pulverizer MC Pulverizer

Lightweight and Powerful

TAGUCHI MC Series Pulveriser Continues to Evolve

MC series Pulverizer is designed for pulverizing various types of concrete.

It is useful in various job sites such as demolition, scraps, road repair, and general civil engineering.

Lightweight and Powerful

Pulverizing work with low-vibration and low-noise

Our in-house original cylinder has realized overwhelming weight reduction. An original design that stores the rod inside the main unit enables work at maximum output all the time without worrying about damage to the rod part.

A compact design can provide low noise and low vibration pulverization.

The main frame has a seamless structure without welding. The reduced overall length and compact design bring the center of gravity closer to the excavator itself for improved stability. Low vibration work can reduce the burden on the workers. In addition, the speed valve block that increases the extension (closing) speed of the cylinders comes equipped as standard. This improves work efficiency.

Easy Maintenance

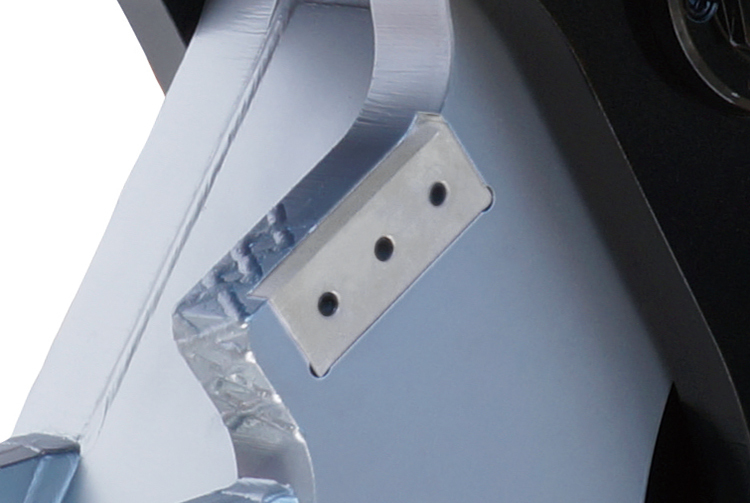

Special Steel Blade

The special steel blade as standard feature can be used on 4 sides reversible. It is possible to cut the rebar that appears during pulverizing work.

The tooth is also made of special steel and it is easy to replace and repair.

SPEC

| Model name | Class of excavator[ton] | Operating pressure[MPa] | Max. operating pressure[MPa] | Length A[mm] | Max. jaw opening B[mm] | Cutting blade length C[mm] | Crushing force at tip D[kN] | Crushing force at center E[kN] | Mass[kg] |

|---|---|---|---|---|---|---|---|---|---|

MC-36 | 3 - 5 | 24.5 | 24.5 | 960 | 430 | 70 | 178 | 282 | 240 |

MC-52 | 3.5 - 5.5 | 24.5 | 24.5 | 1120 | 510 | 70 | 226 | 353 | 380 |

MC-75 | 6 - 8 | 24.5 | 27.4 | 1270 | 620 | 100 | 369 | 534 | 590 |

MC-135 | 12 - 14 | 31.4 | 34.3 | 1470 | 750 | 120 | 547 | 882 | 1030 |

MC-212 | 20 - 22 | 31.4 | 34.3 | 1800 | 885 | 160 | 725 | 1170 | 1670 |

MC-302 | 30 - 37 | 31.4 | 34.3 | 2040 | 1020 | 180 | 690 | 1140 | 2430 |

MC-352 | 30 - 37 | 31.4 | 34.3 | 2130 | 1050 | 180 | 1060 | 1740 | 2830 |

MC-452 | 40 - 45 | 31.4 | 34.3 | 2730 | 1170 | 210 | 1220 | 1930 | 4000 |

・ Single two-way hydraulic piping is required.

・ We recommend reinforcing the stick of a hydraulic excavator that has this product installed.

・ The attachment cannot be installed on a hydraulic excavator of a different class.

・ For models compatible with MC-36, contact your Taguchi dealer.